ABOUT US

iRefine Systems offers Electrical and Automation engineering solutions for mining, cement and wastewater industries. Our main objective is to deliver exceptional services and solutions to our clients, we do so by ensuring that our solutions are scalable, flexible, and efficient and delivered with integrity, transparency and commitment.

iRefine Systems strive to achieve high quality, sound and reputable technologies through optimizing operational systems and further promoting simplicity to existing systems. We are a reliable and dedicated enterprise that is steered to afford a sustainable future for our customers. We operate and experience in the Mining, Metals & Minerals, Water and Waste and Power sectors.

iRefine Systems Mission is to understand customers’ plant operational needs, and provides a well-thought sustainable,

future-proof solutions, to solve everyday plant efficiency and maintenance challenges.

iRefine Systems Vision is to be the world’s most reliable, trusted and efficient industrial control systems maintenance partner.

iRefine Systems Core Values are integrated in everything we do. These are our three main pillars supports and protects our company’s vision and mission.

Trust-Respect-Integrity

WHAT WE KNOW

We are skilled in the following major industrial software engineering

WHAT WE DO

We are skilled in the following major industrial software engineering

Staying relevant with evolving technology is crucial for every industrial operation. Outdated plants risk high downtime and missed production targets, affecting efficiency, device integration, and critical spares management. We assist industries in overcoming workforce challenges, including the retirement of experienced workers, by modernizing legacy systems. This ensures that upcoming generations can maintain and operate efficiently, securing the future of your operations.

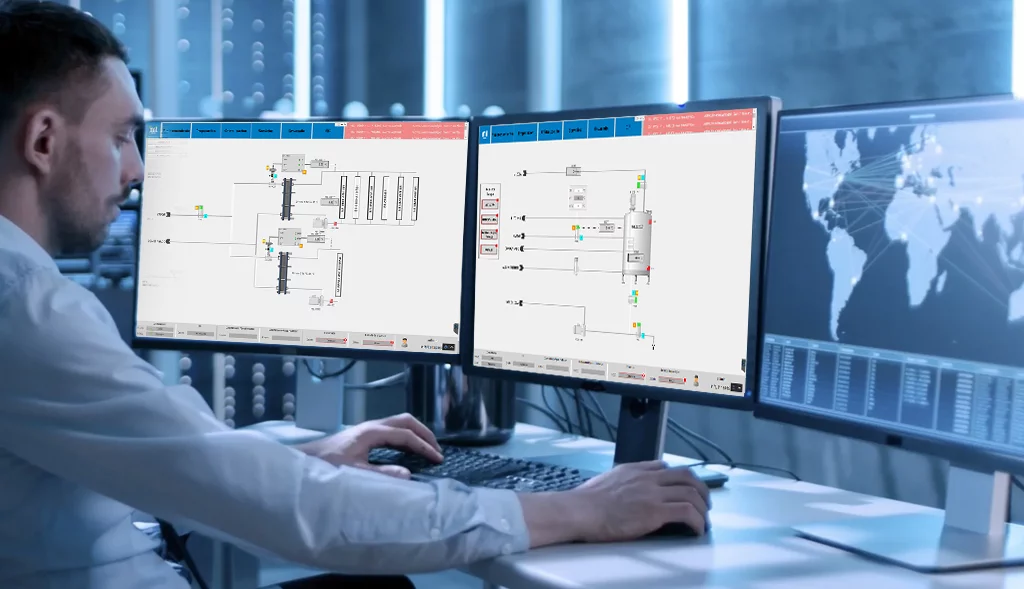

New generation HMIs and SCADA systems provide enhanced user experiences with advanced features like adaptive interfaces and context-aware automation. Previously, criteria focused on licenses, tags, and screens, but digital solutions have evolved rapidly. Plant managers now upgrade SCADA/HMI systems to empower their workforce, prevent unexpected downtime with advanced software, and retain talent before the old systems become unsupported. These innovations are essential for modern industrial operations.

We are proud to highlight our specialized Siemens PCS 7 DCS migration and upgrade services. Our expert team ensures a seamless transition from legacy systems to the advanced Siemens PCS 7 platform, minimizing downtime and maximizing productivity. From initial assessment and planning to implementation and post-upgrade support, we provide comprehensive solutions that enhance automation infrastructure, optimize performance, and future-proof operations for our clients.

Let us help you manage energy efficiently with our state-of-the-art operation and monitoring software. Our advanced solutions allow real-time measurement and monitoring of all energy-consuming devices, including electrical, water, and gas systems, within a unified platform. This comprehensive view enables informed decisions, optimized resource allocation, and reduced operational costs. Ensure peak efficiency, enhance sustainability, and improve overall performance with iRefin’s cutting-edge software. Partner with us for energy efficiency and operational excellence.

Companies today are facing internal and external pressures to produce more with less, and to increase profits while reducing expenditure. iRefine assists with managing and optimizing production yields, and with stabilizing plant output and plant safety while managing the cost-effectiveness strategies of your maintenance expenditure.

End results being a higher production process that is finely tuned and expertly managed to maximize profits.

Industries continue to combat two main challenges, maximizing the plant availability while reducing operating cost. These challenges play out against the backdrop of shortages of expertise to adequately maintain plant control systems. The key question is how to leverage a maintenance contract to make a real impact on the bottom line? If there are equipment issues, how can these be resolved quickly, without compromising plant safety?